Ruhr-Universität Bochum

Feststoffverfahrenstechnik

IC 3-51/55

Universitätsstraße 150

44801 Bochum

Ulrike Harnickell

Gebäude IC 3 Raum 51/55

+49 (0) 234 32-26685

sek@fvt.rub.de

In the food industry, flavorings are often encapsulated to improve shelf life and dosage. Spent yeast cells, which are a waste product from breweries, are a particularly inexpensive and sustainable encapsulation material. If these are extracted after brewing to produce yeast extract, encapsulation even represents a tertiary use. On this basis, bio-based controlled release systems can be produced in a resource-saving manner and free of additives.

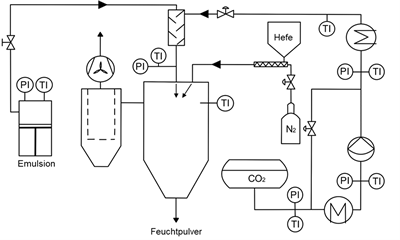

At the Chair of Solids Process Engineering, aroma is encapsulated in the yeast using a high-pressure spray process (concentrated powder form). At around 100 bar, an emulsion of aroma oil and water is mixed with supercritical CO2 and expanded in a spray tower. The subsequent expansion of the CO2 causes the emulsion to nebulize in an inert atmosphere. At the same time, yeast is pneumatically fed into the spray tower. This enables uniform and defined wetting of the yeast in the air. In the resulting moist powder, the yeast cells can absorb the aroma simply by adding heat. Subsequent air drying is sufficient to obtain a free-flowing dry powder. The technology used differs significantly from the conventional encapsulation process. Traditionally, an excess of flavor and water is mixed with yeast. The resulting suspension is difficult to handle in terms of process engineering. This applies in particular to the drying process, which requires complex procedures for soaked yeast. In the Concentrated Powder Form process, on the other hand, the yeast is not suspended at all.

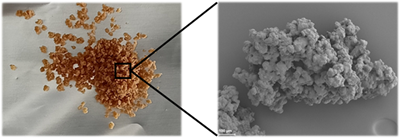

The yeast capsules produced in the pilot plant achieve mass loadings of over 20 % aroma oil. Immediate release can be achieved by remoistening the dry powder. The encapsulation success as well as the release behaviour in different model environments are measured by means of gas chromatography with flame ionization detection. The capsules offer excellent protection against oxidation and can be stored for well over a year without loss of aroma. In addition, temperature resistance up to at least 200°C has been demonstrated by thermogravimetry.

Concentrated Powder Form

System diagram

Final product